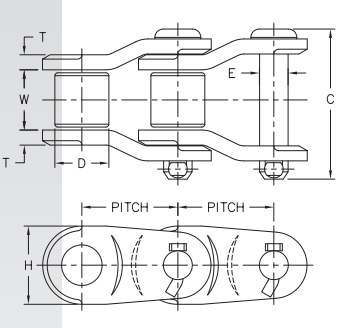

Engineering Class Drive Chain is designed for power drives, construction machinery and conveyors. It operates under the most serious ailments at moderately substantial speeds. It’s created according to ANSI or manufacturer’s specifications. It might be interchanged with standard chains of other producers, depending on the size. You can find 4 simple styles.

Type one

Conventional offset design includes a roller, bushing, pin and common offset sidebars

Type 2

Distinctive made offset sidebars possess a roller, bushing, pin and offset sidebars  which have been specially formed to optimize articulation where

which have been specially formed to optimize articulation where

Type 3

Steel bushed offset sidebar chain includes a bushing, pin and offset sidebars. It does not have a roller

Style four

Straight sidebar drive chain has a roller, bushing, pin and straight sidebars

MXS and other drive chain is obtainable with pitch presently ranging from 1.500” to 7.000”. Average greatest power ranges from 20,000 to 600,000 pounds and functioning loads are available from two,300 to thirty,600 lbs. Drive chains can be found in cottered construction only. the pins are press fitted into the sidebars, preventing pin rotation all through chain operation. This also acheives optimum bearing surface in between the pin along with the sidebar. Offset drive chain should be run with all the closed finish 1st since the course of travel. Sprockets are available for all applications of our chain.

car drive shaft

As one of car drive shaft manufacturers, suppliers and exporters of mechanical products, We offer car drive shaft and many other products.

Please contact us for details.

Mail: [email protected]

Manufacturer supplier exporter of car drive shaft.

Recent Posts

- China OEM Auto Parts Drive Shaft for CHINAMFG Sunny Teana Navara Pickup Car Accessories CV Axle Shaft

- China Good quality CHINAMFG SWC-Bh Types Cardan Drive Shaft for Rolling Mill, Steel Mills Industry, Paper Mill Machinery

- China factory Concrete Vibrator Shaft/Flexible Drive Shaft/Drain Cleaning Shaft (JYG8.10.11.12.13)

- China Good quality 936-310 New Front Propeller Shaft Drive Shaft 26209488491 26207629987 for BMW

- China supplier Custom Lathe Parts Automotive Accessories Stainless Steel Precise CNC Machining Car Drive Shafts

- China Custom Applicable to CHINAMFG Fspace Front Drive Shaft, Land Rover Star Pulse Front Drive Shaft, Lr092699 T4a1861

- China Best Sales Car Auto Parts Axle Shaft Front Left Right CV Axle Drive Shaft for CHINAMFG Corolla Camry CHINAMFG Mazda Suzuki CHINAMFG Pajero CHINAMFG

- China manufacturer Custom Lathe Parts Automotive Accessories Stainless Steel Precise CNC Machining Car Drive Shafts

- China Hot selling Construction Machinery Spare Parts Excavator Transmission Shaft Wheel Loader Drive Shaft for Shangong 655D Z520100040 Z520100030 Z520100020

- China factory Rear Drive Shaft for Audi A4 A5 A6 A8 Q3 Q5 Q6 Q7 Quattro Transmission Shaft Propshaft

- China factory OEM ODM Cardan Transmission Tractor Parts Pto Drive Shaft for Agriculture Machinery

- China Good quality Car Auto Parts Axle Shaft Front Left Right CV Axle Drive Shaft for CHINAMFG Corolla Camry CHINAMFG Mazda Suzuki CHINAMFG Pajero CHINAMFG

- China wholesaler Uaz and Niva and Gaz and Maz and Kamaz and Mtz, Zil Cardan Shafts

- China factory Precision Transmission /Drive/Axle/Auto/Spline/Machinery Parts/ Rotor Gear Customized Machining Knurling Shaft

- China OEM Flexible Inner Shaft/Flexible Drive Shaft/Flexible Shafts for Drain Cleaning/Transmission Shaft

- China best Control Within 0.005mm Great Quality Factory Price Drive Shaft Made by Aluminum

- China wholesaler CE Certificate Agricultural Machinery Potato Harvester Spare Parts Cardan Pto Drive Shaft and Farm Tractor Pto Shaft

- China best Rear Drive Shaft for Audi A4 A5 A6 A8 Q3 Q5 Q6 Q7 Quattro Transmission Shaft Propshaft

- China Professional for Mercedes Benz C240 / Gl / Ml / Sprinter / Vito Transmission Drive Shaft Propeller Shaft Kardanwelle

- China manufacturer High-Quality for Mercedes Benz Ml270 Driveshaft Assembly

- China Hot selling Construction Machinery Spare Parts Excavator Transmission Shaft Wheel Loader Drive Shaft for Shangong 655D Z520100040 Z520100030 Z520100020

- China supplier Applicable to Porsche Cayenne Volkswagen Touareg Transmission Shaft Drive Shaft Half Shaft 7p0521101q 95842101001touareg Drive Shaft Cayenne Drive Shaft

- China manufacturer Auto Parts for CHINAMFG RAV4 Drive Shaft Propelle Shaft 37100-42050

- China Professional Custom 300m 4340m 4340 Axle Shaft High Precision Drive Shaft Gear Shaft for Car

- China factory Auto Parts for CHINAMFG RAV4 Drive Shaft Propelle Shaft 37100-42050

- China manufacturer Flexible Inner Shaft/Flexible Drive Shaft/Flexible Shafts for Drain Cleaning/Transmission Shaft

- China Professional CHINAMFG Auto Parts Drive Shaft for CHINAMFG Honda CHINAMFG Mazda CHINAMFG CHINAMFG Car Accessories CV Axle Shaft

- China Professional Uaz and Niva and Gaz and Maz and Kamaz and Mtz, Zil Cardan Shafts

- China manufacturer Machinery Parts Rotor Gear Shaft Customized Machining Knurling High Precision with Factory Price for Auto Drive Factory Price

- China Good quality OEM ODM Cardan Transmission Tractor Parts Pto Drive Shaft for Agriculture Machinery

- China Custom CHINAMFG Factory CV Axle Components Left Drive Shaft for Chevrolet Epica 2.0 at Mt 2007-2009 C-GM053-8h

- China Good quality 2% off CHINAMFG Front CV Axle Left Right CV Drive Shaft Supplier for CHINAMFG CHINAMFG Honda CHINAMFG CHINAMFG CHINAMFG VW Mazda BMW

- China Professional Agriculture Pto Drive Shaft for Earth Mover and Potato Harvester

- China manufacturer China Gearbox Parts Drive Shaft Me636001 6D16 for CHINAMFG

- China Good quality Precision Transmission /Drive/Axle/Auto/Spline/Machinery Parts/ Rotor Gear Customized Machining Knurling Shaft

- China manufacturer CHINAMFG Car Spare Auto Parts Front CV Axle Drive Shaft for CHINAMFG CHINAMFG Honda CHINAMFG Mazda CHINAMFG Car Accessories Axle C. V. Joint

- China manufacturer Professional Drive Shaft Cardan Shaft with High Performance for Rolling Mill

- China Standard Auto Car Transmission Front Axle Left Drive Shafts OE 5475507

- China best Gjf Brand Wholesale Auto Shaft Left OEM Drive Shaft for Mazda M3 Bm 1.5 at 2014 C-Mz087-8h

- China Best Sales Propeller Shaft Factory +700 Items for CHINAMFG / Jeep / Chevrolet / CHINAMFG / Honda / BMW / Mercedes / Subaru / CHINAMFG Drive Shafts

- China high quality Rear Drive Shaft for Audi A4 A5 A6 A8 Q3 Q5 Q6 Q7 Quattro Transmission Shaft Propshaft

- China Hot selling Customized Forged Steel Pinion Shaft High Quality Drive Large Gear Shaft

- China best OEM Core Competencies Steel Roller High Temperature Resistant Shaft Machine Part Steel Bar Drive Shaft

- China Standard Construction Machinery Spare Parts Excavator Transmission Shaft Wheel Loader Drive Shaft for Shangong 655D Z520100040 Z520100030 Z520100020

- China Best Sales Brand New Dodge Freightliner Driveshaft Center Support Front or Rear 9064100381 CHINAMFG Auto Parts for Best Quality

- China Professional Custom CNC Shaft 304 CNC Machined Long Shaft Motor Drive Shaft

- China wholesaler Custom CNC Shaft 304 CNC Machined Long Shaft Motor Drive Shaft

- China Custom Custom CNC Shaft 304 CNC Machined Long Shaft Motor Drive Shaft

- China Hot selling Custom CNC Turning Steel Alloy Swing Motor Transmission Drive Pinion Gear Shaft

- China wholesaler Agriculture Machine Accessory Drive Axle Transmission Shaft Power Drive Pto Shaft

- China OEM Machinery Parts Rotor Gear Shaft Customized Machining Knurling High Precision with Factory Price for Auto Drive Factory Price

- China OEM Car Auto Parts Axle Shaft Front Left Right CV Axle Drive Shaft for CHINAMFG Corolla Camry CHINAMFG Mazda Suzuki CHINAMFG Pajero CHINAMFG

- China best Gjf Car CV Joint Drive Shaft for CHINAMFG Hilux Vigo Kun25 Tgn26 Kun51 43430-0K020 2004-Hot Sale Products

- China supplier Gjf Car CV Joint Drive Shaft for CHINAMFG Hilux Vigo Kun25 Tgn26 Kun51 43430-0K020 2004-Hot Sale Products

- China Custom New Front Propshaft Drive Propeller Shaft 26209425906 26207629988 for BMW

- China Standard Shaft CNC Machining Shaft Flange Shaft Roller Shaft Drive Shaft Gear Shaft Spline Shaft Logistics Equipment Shaft Conveyor Shaft Coater Shaft

- China factory for Mercedes Benz C240 / Gl / Ml / Sprinter / Vito Transmission Drive Shaft Propeller Shaft Kardanwelle

- China Hot selling Flexible Inner Shaft/Flexible Drive Shaft/Flexible Shafts for Drain Cleaning/Transmission Shaft

- China best CHINAMFG Car Spare Auto Parts Front CV Axle Drive Shaft for CHINAMFG CHINAMFG Honda CHINAMFG Mazda CHINAMFG Car Accessories Axle C. V. Joint

- China Good quality Flexible Inner Shaft/Flexible Drive Shaft/Flexible Shafts for Drain Cleaning/Transmission Shaft

- China Professional CHINAMFG Factory CV Axle Components Left Drive Shaft for Chevrolet Epica 2.0 at Mt 2007-2009 C-GM053-8h

- China Best Sales High-Quality Hilux Vigo Front Drive Shaft for CHINAMFG

- China wholesaler Propeller Shaft / Drive Shaft for CHINAMFG 4runner / Hilux / Tundra / Tacoma / Land Cruiser Hot Sell America & Europe Market

- China OEM 938-269 52111596AA; High-Quality Drive Shaft for Jeep Liberty 2005-2007

- China Good quality Auto Parts Drive Shaft for CHINAMFG Sunny Teana Navara Pickup Car Accessories CV Axle Shaft

- China best for BMW/ Benz / Audi / CHINAMFG / VW / Land Rover Propeller Shaft Drive Shaft America Market Hot Sell